They fit very easily into your existing heat losing device to change it into an effective heat source. You will find a number of different kinds of fireplace inserts available on the market nowadays. Electricity, by the way is not an issue too as the electricity consumption of the products is fairly low.

How To Frame For A Fireplace Insert

The way an electric powered fireplace insert functions is uncomplicated. You can also prepare yourself by thinking of the safety as well as convenience of making the fireplace of yours better for your family members. Once the gas fireplace insert is actually installed, it won't demand lots of upkeep.

Get the Look: Rustic Mantels Traditional Home

With an immediate vent gas fireplace, eighty five % of generated heat remains in the building. A lifeless hearth is most certainly not something you would prefer in the home of yours. They may look like the standard fireplaces that made use of wood burning for heating purposes but they operate solely on energy.

Hirondelle Rustique: DIY Stacked Stone Fireplace (First Remodeling Project Part 2)

DIY Electric Fireplace Build

Quadra-Fire 4100i wood insert Energy Tech Services (Kenora) Inc.

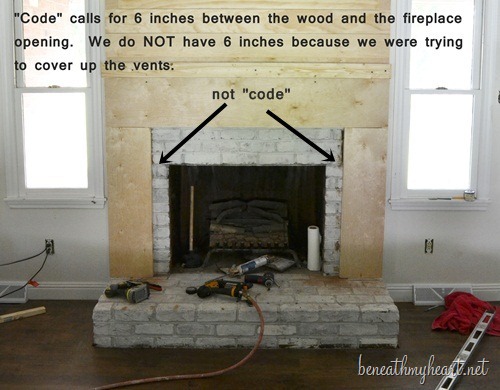

How to build a Fireplace Surround – Beneath My Heart

Build a Fireplace Insert Draft Stopper {a Lowe’s Creator Idea} – Pretty Handy Girl

Image result for floor to ceiling fireplace tile Fireplace surrounds, Fireplace tile, Slate

Related Posts:

- Compact Electric Fireplace Insert

- 24 Gas Fireplace Insert

- Gas Burning Fireplace Inserts Reviews

- Craftsman Fireplace Insert

- Silent Flame Fireplace Insert Manual

- Energy King Fireplace Insert

- How To Repair Cracked Fireplace Insert

- Sears Gas Fireplace Inserts

- 3 Sided Wood Burning Fireplace Inserts

- Heat And Glo Gas Fireplace Inserts