These open fireplace screens can be quite an easy flat screen, could be free standing on leg brackets and could be the more prevalent three-sided screen. A typical hearth display screen is mesh curtains that slide from the center to both sides. You have to make sure that the fireplace screen you choose has protective and decorative capabilities.

Fireplace Screen Mesh Material

If you have a far more traditional looking house, for example a Craftsman or perhaps Victorian, you do not wish to opt for a modern or contemporary fire screen – it will look from place. A fireplace display is among the important accessories of its since it is able to increase the fad of a hearth.

Mesh Fireplace Screen – Frontgate

Five-paneled screens are well suited for fireplaces which have massive openings. Fireplace screens are one of the vital items of the hearth business. But how can we find out which one is suitable for us, much less for our interior? They make children secure. Choose from single panel screens, 3,4,or 5 panel folding screens, and spark screens.

Fireplace Mesh Screens by Condar

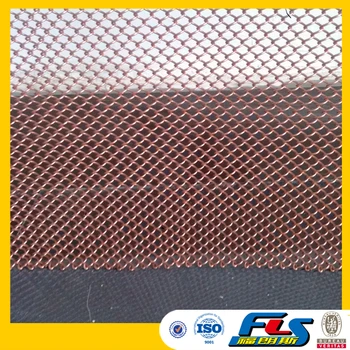

Antique Brass Fireplace Wire Mesh Screen – Buy Antique Brass Fireplace Wire Mesh Screen

Monogrammed Iron Gate Firescreen Firescreen, Fireplace, Fireplace screen

3-Panel 47x29in Simple Steel Mesh Fireplace Screen w/ Rustic Worn Fini – Best Choice Products

Arden Single Panel Mesh Fireplace Screen – Stainless Steel PlowHearth

Fireplace mesh screens,Fireplace mesh screens manufacturer-Wuzhou Kingda Wire Cloth Co. Ltd

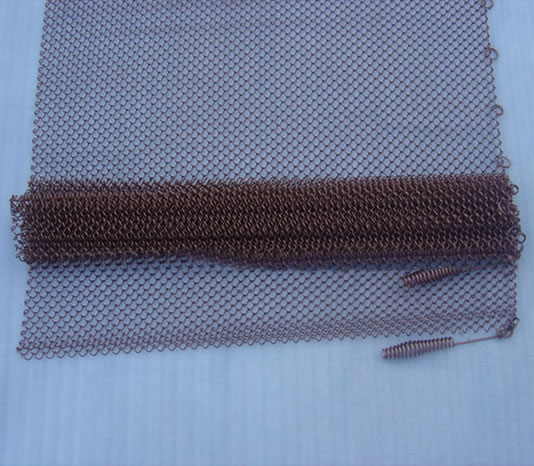

Chain Link Mesh, Spark Mesh, Fireplace Mesh Curtains, Replacement Screen

Fireplace Mesh Screen – For Sale Classifieds

Amazon.com: Fireplace Screens 3-Panel Metal Mesh Fireplace Screen, Living Room Home Decor with

Fireplace mesh screen Wire Mesh Manufacturer ZhongDi

Best Selling Home Decor Haddon Modern Iron Fireplace Screen, Matte Black in the Fireplace

Fireplace Screen Mesh – Buy Fireplace Screen,Fireplace Screen Curtain,Wire Mesh Screen For

Multi Size Chain Link Curtain 304 Stainless Steel Fireplace Mesh Curtain

Related Posts: